Machine-Applied Labels

For efficiency a product manufacturer often uses machinery to rapidly apply their product labels. Label application equipment can maximize productivity when product label usage is high, applying pressure-sensitive labels far faster than hand application.

Labels and Machine Application

Fully automatic labeling machinery is high-speed and accurate. Larger product manufacturers either have their own equipment or outsource to a labeling company. Prior to ordering labels that will be machine-applied you need to know the answer to the questions below to make sure you order the proper labels.

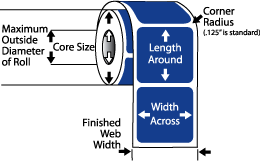

Roll Diameter and Core Size

For machine application, the Maximum Outer Diameter is important to know, as labeling machines vary and have different maximum OD. At the center of the roll of labels is the Label Core. A label core is typically 3″ but some label machines use a different core size. Check with your equipment manufacturer for exact specifications.

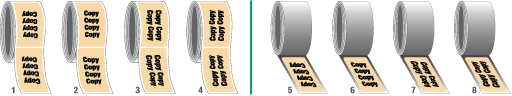

Label Orientation: Unwind Direction

If you are hand-applying your labels then unwind direction does not matter. however, the unwind direction is an important consideration with machine-applied label. If you are applying your labels by machine, or having a contract manufacturer apply the labels then you will need to know the unwind direction. “Unwind” refers to the direction that your labels are coming off the roll. Most labeling machines will only be able to work with one unwind direction for each type of container.

In addition to Unwind Direction and Core Size, there are many different label materials and adhesive choices. We recommend that you read about some of the options in the About Labels page to be sure you are ordering the right labels for your particular situation. Feel free to call TSOQ Printing or email us for a free, no-obligation consultation to be sure that you order the right labels for your particular needs.